2022 DMG MORI NLX2500SY/1250 long bed with milling !

2022 DMG MORI NLX2500SY/1250 long bed with milling !

Description

Basic Machine

NLX 2500 | 1250 - Milling Specification J-A01440* 1

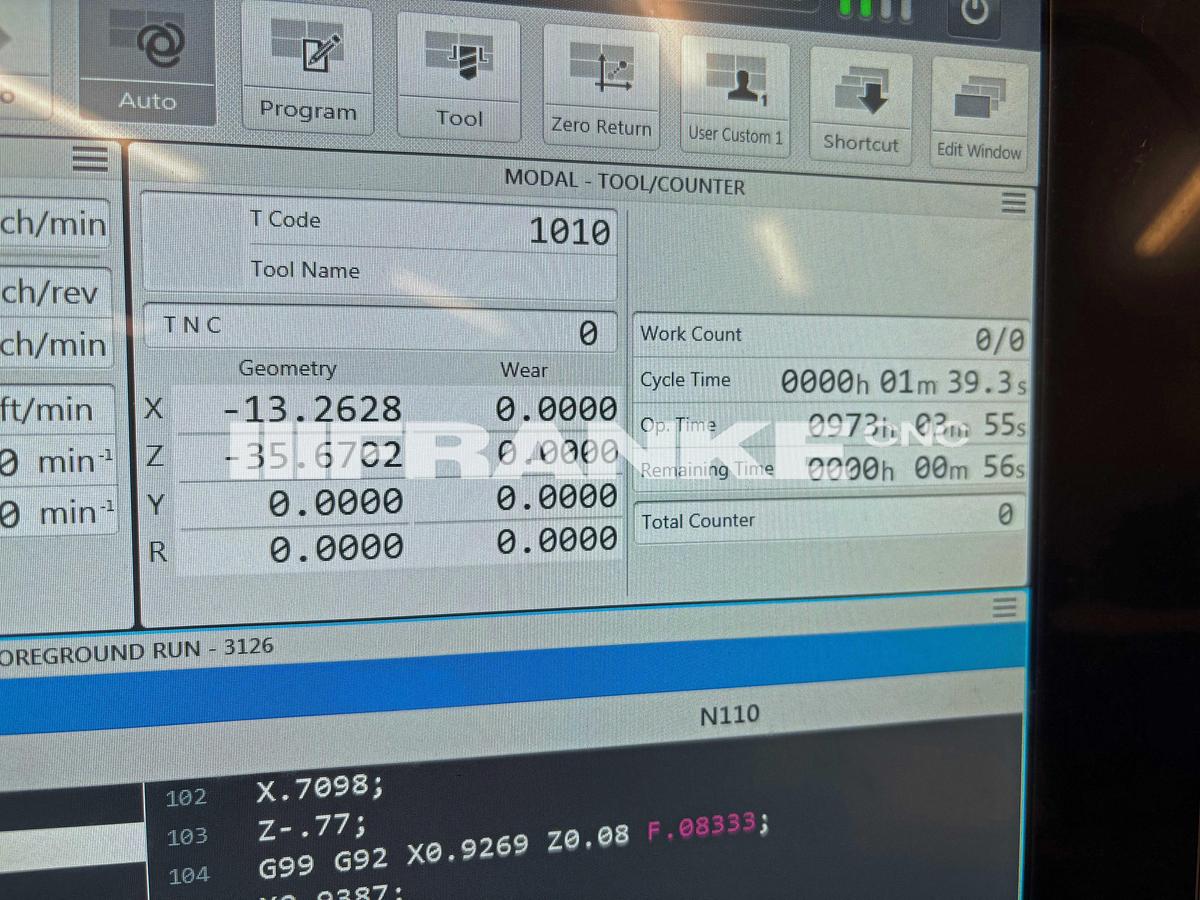

Control

Control M730UM with CELOS (NLX2500) Control unit: Mitsubishi M730UM J-006140* 1

Operation system: CELOS (MAPPS V)

CELOS - ERGOline Touch J-003261* 1

It is a machine operation panel with 21.5-inch multi

touch screen, which realizes comfortable operability. It documents, visualizes and centrally

manages the order, process and machine data,

allowing the networking with CAD/CAM and also

the function extension using applications. The

user-friendly, highly-productive MAPPS system is installed.

Spindle

(Left Spindle) High-Output Spindle 26/26/22 kW, J-016102 1

4,000 min-1

The NLX 2500 adopts a highly reliable spindle

designed to minimize thermal displacement. The

advanced spindle labyrinth structure and the spindle air purge adopted for the machine (option

for the 2-axis turning specification) achieves the

highly durable spindle by preventing coolant from

entering the spindle.

Max. spindle speed: 4,000 min-1 Spindle nose type: JIS A2-8

Through-spindle hole diameter: Φ 91 mm

(dia.3.58 inch.)

Min. spindle indexing angle: 0.001°

Spindle drive motor: 26/26/22 kW (34.7/34.7/30

HP) (25% ED/50% ED/cont)

Spindle torque: 709/500/409 Nm

(522.93/368.78/301.66 ft·lbf) (10 min/30 min/cont)

(Right Spindle) Standard Spindle 11/7.5 kW, 6,000 J-016151 1

min-1

The Right Spindle specification enables

continuous machining of both surfaces. The

combination of rotary tools and the Y-axis function

enables integrated machining from turning to secondary/back face machining, and multi-axis

machining, allowing for process integration.

Right Spindle max. speed: 6,000 min-1

Spindle nose type: JIS A2-5

Through-spindle hole diameter: Φ 43 mm

(dia.1.69 inch.)

Min. spindle indexing angle: 0.001°

Spindle drive motor: 11/7.5 kW (15/10 HP) (25%

ED/cont)

Spindle torque: 77.8/53.1 Nm (57.38/39.16 ft·lbf)

(25% ED/cont)

Chuck for Left spindle (Main spindle)

(Left Spindle) KITAGAWA 10-inch Hollow Chuck J-013368 1

BR10A821

Three-jaw hydraulic chuck manufactured by

Kitagawa Iron Works.

Chuck outer diameter: Φ254 mm (dia.10 inch.)

Through-hole diameter: Φ81 mm (dia. 3.18 inch.) Gripping diameter: Max. Φ254 mm (dia.10 inch.),

Min. Φ31 mm (dia.1.22 inch.)

Jaw stroke (diameter): 8.8 mm (0.35 inch.)

Plunger stroke: 19 mm (0.75 inch.)

Max. allowable pull force: 49 kN (11.01 klbf) Max. static gripping force: 123 kN (27.64 klbf)

Dynamic gripping force at max. speed: 44 kN (9.88

klbf)

Max. allowable speed: 4,500 min-1

Mass: 40.9 kg (89.99 lb.)

*The data above are information on the chuck body. Since it may be limited by this machine

specification, please check the contents of the

mounted cylinder set for details.

(Left Spindle) Hollow Cylinder Set for KITAGAWA J-013383 1

10-inch) Hollow Chuck BR10A821 (Bar work capacity dia. 80 mm (3.15 inch)) (Without Chuck

Body)

Hollow cylinder and draw bar are included as a

set. Chuck is not included. Please see the

chuck-cylinder combination diagram for the

combination with chuck and the specification.

* further description see attachment

Chuck for Right spindle (Counter spindle)

(Right Spindle) KITAGAWA 8-inch Hollow Chuck BR08A521 J-013420 1

Three-jaw hydraulic chuck manufactured by

Kitagawa Iron Works.

Chuck outer diameter: Φ210 mm (dia.8.27 inch.)

Through-hole diameter: Φ66 mm (dia.2.6 inch.)

Gripping diameter: Max. Φ210 mm (dia.8.27 inch.), Min. Φ22 mm (dia.0.87 inch.)

Jaw stroke (diameter): 7.4 mm (0.29 inch.)

Plunger stroke: 16 mm (0.63 inch.)

Max. allowable pull force: 32 kN (7.19 klbf)

Max. static gripping force: 99 kN (22.25 klbf) Dynamic gripping force at max. speed: 33 kN (7.42

klbf)

Max. allowable speed: 5,000 min-1

*The data above are information on the chuck

body. Since it may be limited by this machine

specification, please check the contents of the

mounted cylinder set for details.

(Right Spindle) Solid Cylinder Set for KITAGAWA J-013427 1

8-inch Hollow Chuck BR08A521 (Without Chuck

Body)

Solid cylinder and draw bar are included as a set. Chuck is not included. Please see the

chuck-cylinder combination diagram for the

combination with chuck and the specification.

Options for Turret

Turret Y-axis Specification J-016110 1

It moves the turret in the Y-axis direction. In combination with the rotary tool spindle and right

spindle, it implements process integration for

workpieces with complicated shapes. Please refer

to the turret interference diagrams for the movable

region.

Travel: ± 50 mm (± 1.97 inch.)

Rapid traverse rate: 10 m/min (393.7 ipm)

High-Torque Rotary Tool Spindle 40/14 Nm J-020756 1

(29.5/10.33 ft·lbf), 10,000 min-1

High-torque rotary tool spindle for the

10/12-station in-house bolt-tightened turret

specification. BMT (Built-In Motor Turret) is

installed with the milling specification, and the

cooling jacket suppresses heat generation to

implement excellent machining accuracy.

Rotary tool machining ability: drill Φ 26 mm

(dia.1.02 inch.), tap M20

Rotary tool spindle output: 5.5/5.5/3.7 kW

(7.5/7.5/5 HP) (3 min/5 min/cont)

Rotary tool spindle torque: 40/30/14 Nm

(29.5/22.13/10.33 ft·lbf) (3 min/5 min/cont)

* further description see attachment

12-Station Bolt-Tightened Turret (Standard J-016106* 1

Specification) (Y, SY, SMC)

In-house 12 station turret. Please refer to the axis

travel diagrams and turret interference diagrams

for the movable region.

Number of tool stations: 12

Shank height for square tool: 25 mm (0.98 inch.)

Shank diameter for boring bar: Φ 50 mm (dia.1.97

inch.) (Right spindle side Φ 32 mm (dia.1.26

inch.))

Turret indexing time (1 station): 0.27 seconds

Method for mounting tool on turret: Bolt-tightened

BMT60

Overhang of O.D. Cutting Rotary Tool: 100 mm J-002560 1

(3.94 inch.) (Y-axis Travel Restriction)

The specification to increase the overhang of O.D.

cutting rotary tool from 50 mm (1.97 inch.) to 100 mm (3.94 inch.). The machining chamber rear

cover is partially modified to prevent interference

of the rotary tool.

*The Y-axis stroke is restricted for the use in

combination with the Y-axis specification. (See

Turret Interference Diagrams)

*Please consult DMG MORI when using this

specification with the 20 station turret, as the

interference with the right spindle chuck may

occur.

Tailstock

Right Spindle Tailstock Specification J-003188 1

The specification to push a workpiece by the

center mounted in the Right Spindle chuck. This

allows you to machine the tip of the workpiece.

When using Right Spindle as a tailstock, the motor

equipped with a brake is installed as the spindle may be pushed back.

*The center is not included. Please purchase it

separately.

Coolant supply / Chip removal

Applicable Coolant Type: Water-Soluble Coolant J-G00428 1

If the oil-based coolant is used with the

water-soluble coolant specification, it may cause

poor accuracy, machine troubles or fire. It is

necessary to select the oil-based coolant

specification for using the oil-based coolant.

Interface for Chip Conveyor (Right Discharge) I/F to install the hinge- or scraper-type conveyor. J-003291 1

The discharge port is on the right side of the

machine. The chip conveyor is not included.

Please purchase it separately. The in-machine

chip tray is included.

* further description see attachment

High-Pressure Coolant System (800/1,100 W) J-002147 1

It improves the chip removing performance in

cutting and the tool/workpiece cooling capability.

The pump for supplying coolant to the turret is

changed to the high-pressure specification

(output: 800/1,100 W (50/60 Hz)).

Max. pump pressure: 0.8 MPa (116 psi)

Interface for Super-High-Pressure Coolant J-016822 1

System (8 Steps Pressure) (Separate

Type)(Auto-Switching from/to Standard Coolant

Pump)

Interface for mounting the high-pressure coolant

system (separate type). The electrical

components and coolant piping are included. The

predefined 8 steps of pressure can be selected by

the M-code.

Max. discharge pressure: 7 MPa (1,015 psi)

*The high pressure coolant unit is not included.

*Please prepare the power source supplied to the

high pressure coolant unit separately.

*When using the high-pressure coolant system,

the machining accuracy may be influenced by a

rise in the coolant temperature. Select the coolant

chiller and mist collector to reduce the influence on

the machining accuracy.

Without Coolant chiller J-014458 1

If the coolant chiller is not selected, the units (spindle, tool post) inside the machine might be

heated by the coolant, and thermal displacement

might cause defective machining dimensions.

Please select “Coolant Chiller” which is

recommended option.

Measuring / Monitoring

Manual In-machine Tool Presetter (Pivoting Type) J-017110 1

(Standard)

It simplifies the complicated setup work at the tool

change. The position of the tool nose is measured

precisely by just bringing the tool nose into contact

with the sensor, and the measured value is fed back to NC. The tool presetter can be tilted to the

chuck cover side when not used.

* further description see attachment

Full-Closed Loop Control for X-Axis (Direct Scale J-003331 1

Feedback)

The magnetic scale is used for the X-axis position

sensing, instead of the axis servomotor pulse

encoder. It is not susceptible to ball screw

precision error or thermal displacement. The magnetic scale is mounted parallel to the X-axis,

and the coordinates of the turret position are

directly fed back to the NC unit. This enables the

higher precision positioning.

Resolution: 0.01 µm

(Magnescale)

Manual in-machine tool presetter (removable type) J-017114 1

(Right Spindle)

Automation

Signal Lamp 4 Colors (Red, Yellow, Green, Blue) J-004166 1

The machine status is indicated by the LED color.

It is mounted at top front of machine so that it is

visible from a distance. The power-saving,

maintenance-free LEDs with a viewing angle of

360 degree is adopted. The color specification can

be selected from the following two types:

<Type 1 (Standard)>

- Red: Various alarms

- Yellow: The cycle start prohibited

- Green: Automatic mode operation

- Blue: During Operation mode 2/3 being selected

<Type 2>

- Red: Various alarms

- Yellow: Program end (M02/M30)

- Green: Automatic mode operation

*Buzzer function is not included. Please select the

"Signal Lamp Buzzer" specification separately.

Standard Workpiece Unloader (Built-in Type) J-020288 1

This device automatically receives the completed

workpiece and carries it outside the machine.

Unmanned consecutive operation is possible by

combining it with a bar feeder (separate option).

Can be operated in conjunction with the workpiece conveyor (separate option).

Max workpiece diameter: 80 mm (3.15 inch.)

Max workpiece length: 200 mm (7.87 inch.)

Max workpiece mass: 3 kg (6.6 lb.)

Manual mode operation method): by soft key.

Automatic mode operation method: by M-code.

*Can only be operated with door closed.

*With workpiece length 20 mm (0.79 inch.) or less,

the workpiece may not unload properly. For such

workpieces, consult with DMG MORI in advance.

* further description see attachment

Right Spindle Workpiece Ejector J-020210 1

It is an option for Right Spindle specifications, and

ejects a workpiece by pneumatically actuating a

shaft inside right spindle. The end block can be

replaced by the customer.

EtherNet/IP I/F J-015384 1

I/F for exchanging control signals between the

machine and peripheral equipment using the

EtherNet/IP communication protocol. It is

necessary for connecting the peripheral

equipment that supports EtherNet/IP. The wiring is

saved compared to normal hard wiring

communication as the control signals are

exchanged via the EtherNet communication. This

specification includes I/F for receiving and

executing emergency stop signals transmitted

from peripheral equipment via separate non-LAN cable.

*The LAN cable between the machine and

peripheral equipment is not included.

*When the machine is shipped, the circuit is

short-circuited if there is no external device

connected.

Please make sure to remove the jumper wire when

installing machine at the customer's factory.

* further description see attachment

Interface for Bar Feeder (EtherNet/IP Interface) J-020320 1

With Terminal Block for Power Supply

The connection I/F using EtherNet/IP, for the bar

feeder which automatically supplies bar stock to

improve the productivity. Bar feeder body is not

included in this specification.

(Caution) It is necessary to arrange the guide bush

or guide pipe by separate quotation.

*Because the guide bush is solid, please

machining it according to the inner diameter

required by the customer.

*When arranging the guide pipe, specify the pipe

inner diameter in advance.

*In automated machine operations using the bar

feeder, the machine door or shutter is not opened

or closed for long hours.

As a result, a temperature inside the machine can

rise, affecting machining accuracy.

So the mist collector is recommended that can

prevent the temperature from rising.

*When using a bar feeder that cannot discharge

the remaining material inside the bar feeder

equipment, please arrange a workpiece unloader

separately because it is necessary to discharge

the remaining material into the machine.

(Although DMGMORI do not recommend it, when

discharging the remaining material by dropping it

onto chip conveyor without a workpiece unloader,

please cut down the remaining material as much as possible before dropping it onto chip conveyor.

(If the remaining material is too long, it may get

caught in chip conveyor and cause chip conveyor

to break prematurely.)

*When the machine is shipped, the circuit is

short-circuited if there is no external device

connected.

Please make sure to remove the jumper wire when

installing machine at the customer's factory.

General Options

Voltage of Customer Factory 220 V J-G00951 1

This machine is shipped with voltage set to 220 V specification.

(Caution)

IF the setting is incompatible, there is a possibility

of trouble such as operation abnormality and

alarm occurrence. Be sure to check the supply

voltage and frequency of the customer's factory.

* further description see attachment

Frequency 60 Hz J-G00961 1

This machine is shipped with frequency set to 60

Hz specification.

(Caution)

IF the setting is incompatible, there is a possibility

of trouble such as operation abnormality and alarm occurrence. Be sure to check the supply

voltage and frequency of the customer's factory.

Setting Unit, Inch J-004472 1

The unit to be used for the screen display and

program commands is set to "inch".

Turning: "Inch" specification for the turret

Technology Cycle

Alternating Speed J-015571 1

It can suppress regenerative chattering by

fluctuating spindle speed. The cycle is

automatically calculated only by setting the

fluctuation width in the guidance screen.

*Regenerative chatter is created by excitation

resulting from the fluctuation in chip thickness. In

general, the spindle speed needs to be adjusted

as a countermeasure for keeping the chip

thickness constant.

This function is not available when left and right spindles are synchronized(M34 or M35 command)

Options for Control

Addition of Optional Block Skip (Soft Key Type J-008201 1

2-9)

8 optional block skip functions are added. The

switches for enabling/disabling them is added on the operation panel.

(How to Use)

By programming a slash “/” and the number (/n

(n=2 to 9) ) following it at the beginning of a block

and turning on the optional block skip switch with

the same number as programmed on the screen or machine operation panel, the information of the

block is ignored in the DNC or memory operation.

Turning off the optional block skip switch n

enables the information of the block with n.

Namely, the block including /n can be skipped by

the operator’s selection.

X-axis Direction, JIS/ISO-compliant J-G00618 1

The X-axis movement direction is compliant with

the JIS/ISO standard.

* further description see attachment

Machine is offered subject to availability, prior sale, and terms & conditions of FRANKE CNC Sales Agreement. To the best of our knowledge all details listed are deemed correct. It is the Buyer's responsibility to confirm all details including condition, capacity, suitability or performance and we encourage an under power inspection of the machine(s) and accessories prior to purchase.

Price quoted is FOB Purchase Point.

Price quoted includes professional de-installation and shipping preparation by Seller.

Price quoted includes the cost of loading onto truck supplied by Buyer.

Specifications

| Manufacturer | DMG MORI |

| Model | NLX2500SY/1250 |

| Year | 2022 |

| Condition | Used |

| Stock Number | 064556 |