2012 DMG MORI 2nd gen DMU 50 full 5-Axis VMC loaded with automation prep !

2012 DMG MORI 2nd gen DMU 50 full 5-Axis VMC loaded with automation prep !

Description

*Approximately 7,868 Spindle Run hours total, over the life of the machine*

HIGHLIGHTS:

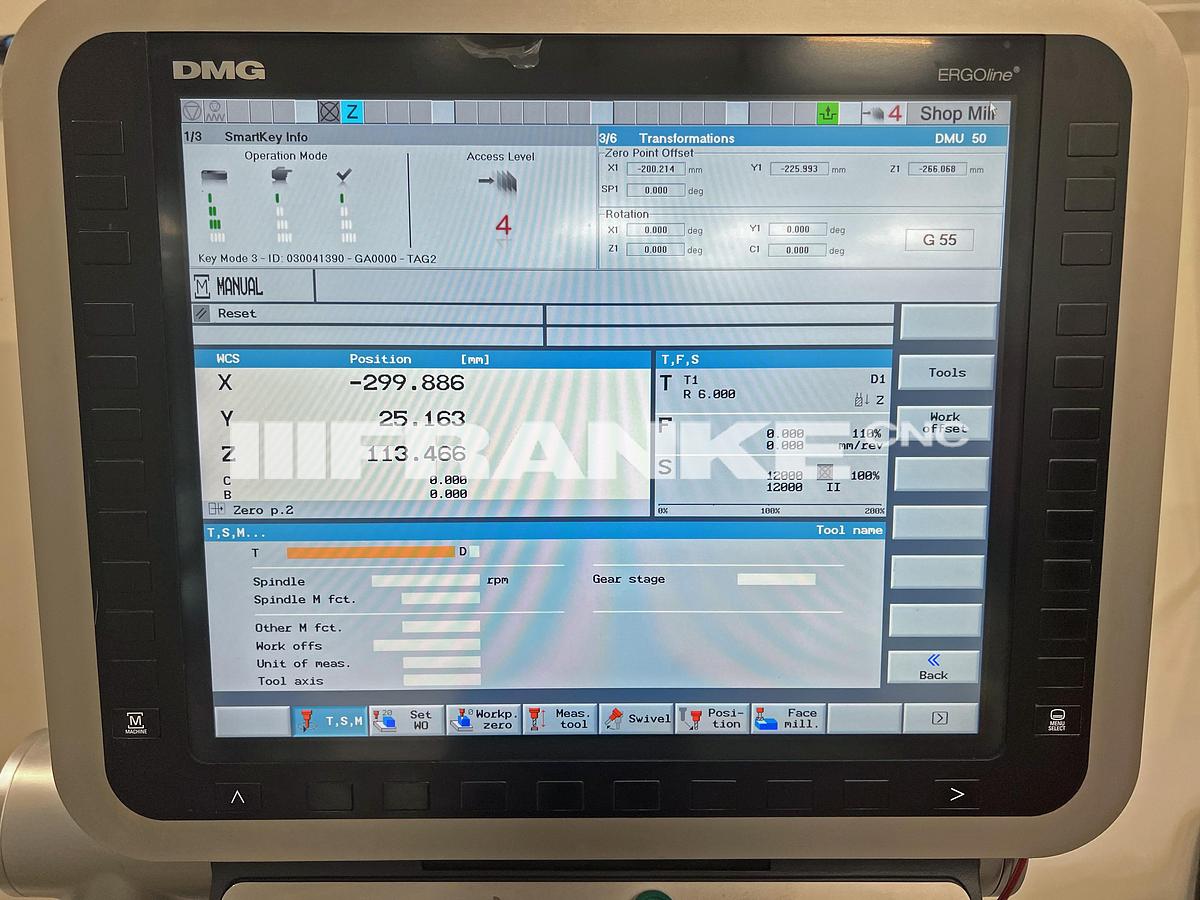

-NEW DMG Design: DMG ERGOline Control, 19" display, DMG LIGHTline

-Optimum space economy: Excellent accessibility to the work area, good chip disposal and steeply slanted walls, large working area in relation to small machine size

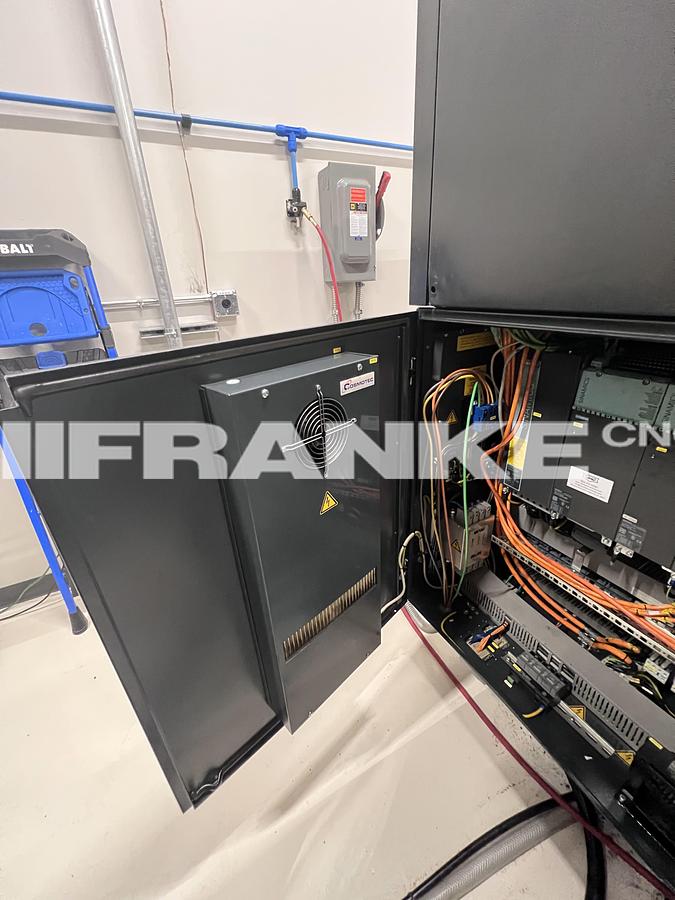

-Digital drives and direct measuring systems: guarantee highest precision and top surfaces

-Mounting of tool magazine parallel to production time

-Powerful integrated motor spindle with up to 14,000 rpm and 30 hp.

-3D-control technology with 19" TFT screen, SIEMENS 840D solutionline with ShopMill Open

AUTOMATION PREPARATION FOR HANDLING SYSTEM/INTERFACE VIA M65

The installation of a handling system (for example, EROWA Robot Easy UPC/Robot System ERS, or System 3R) increases the efficiency of the machine by reducing idle times, like 2nd or 3rd shift or to run over the weekend lights out, unattended. The handling system takes up the job of the workpiece change.

Scope of preparation includes:

-Electrical interface (done by M 65)

-Automatic guillotine door in the right side of the cabin

-Hydraulic clamping of workpiece through swivel rotary table (2 channels). Hydraulic lines are led through rotary leadthrough located at the front of the rotary table. Control pressure switches are on the hydraulic control unit. The separate external hydraulic control unit includes an electrical cabinet and one clamping circuit (2 connections) and can be placed beside machine within range of cable.

Possible features of handling system to be provided by customer:

-Clamping in the chuck and releasing by hydraulic pressure (channel 1)

-Control of proper seating of pallet on chuck (channel 2)

-Flexible linking of various programs and workpieces possible with additional management system

EQUIPPED WITH:

-Visiport spin inspection window on front door

-Fully enclosed cabin guarding with cabin roof for CTS

-Direct measuring system HEIDENHAIN glass scales X/Y/Z

-Direct measuring system HEIDENHAIN rotary encoders B/C

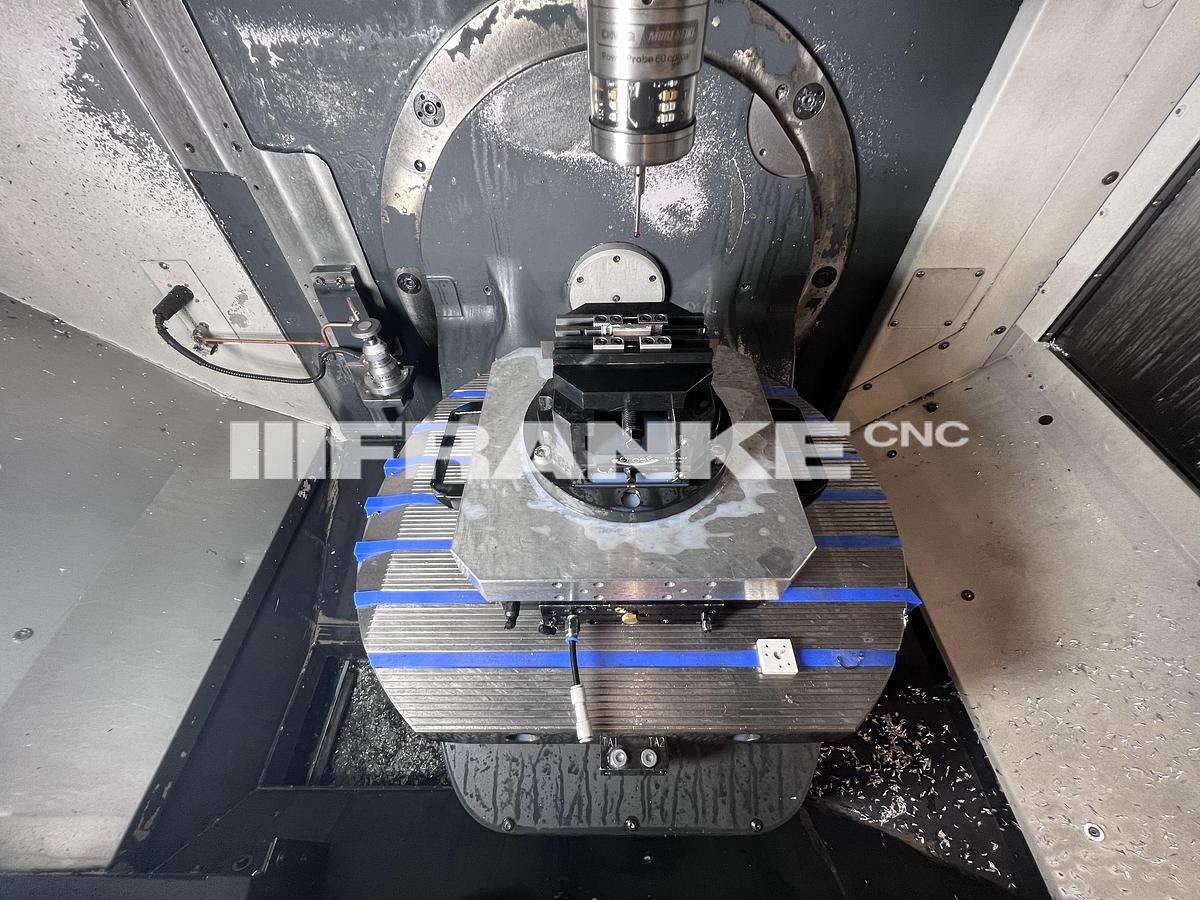

-Swivel Rotary Table for simultaneous machining including working plane transformation

-Renishaw infrared touch probe type PP 60 optical (OMP 60) Power Probe

-HEIDENHAIN TT 140 sensing system for tool measurement and breakage control

Measures the tool length and radius with the spindle at rest or rotating

-3D quickSET tool kit for control and compensation of the kinematic accuracy of 5 axis machine configurations

-Internal coolant supply with paper type filter, 600l tank

30 bar/435 PSI coolant thru the spindle (CTS)

-Rotary joint in spindle for CTS

-Chip conveyor, scraper type

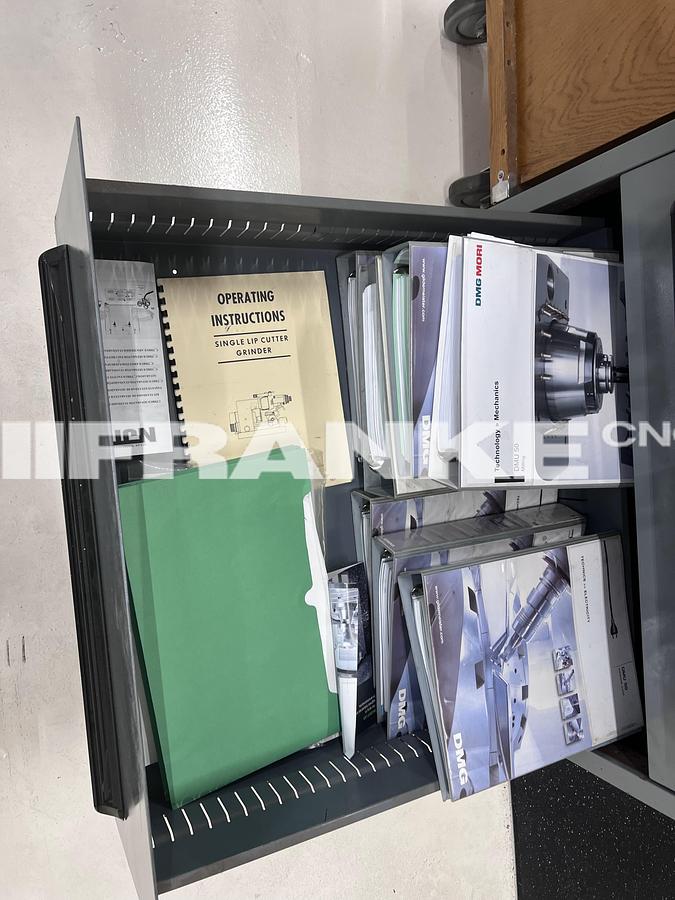

Machine is offered subject to availability, prior sale, and terms & conditions of FRANKE CNC Sales Agreement. To the best of our knowledge all details listed are deemed correct. It is the Buyer's responsibility to confirm all details including condition, capacity, options, suitability or performance and we encourage an under power inspection of the machine(s) and accessories prior to purchase.

Price quoted is FOB Purchase Point.

Price quoted includes professional de-installation and shipping preparation by Seller.

Price quoted includes the cost of loading onto truck supplied by Buyer.

Specifications

| Manufacturer | DMG MORI |

| Model | DECKEL MAHO DMU 50 |

| Year | 2012 |

| Condition | Used |

| Stock Number | 064546 |

| Travel X | 19.7" |

| Travel Y | 17.7" |

| Travel Z | 15.7" |

| Spindle speed range | 20-14,000 rpm |

| Spindle power | 30 hp. |

| Spindle taper | HSK63 |

| Rapid Feed Traverse X/Y/Z | 78.7 ft/min (24 m/min) |

| Integrated swivel rotary table for simultaneous machining clamping surface | 24.8" diameter x 19.7" (630 mm x 500 mm) |

| Table swivel range | -5 to +110 degrees |

| Table rotary axis | 360 degrees |

| Table maximum load | 440.9 lbs. |

| Automatic tool changer type | Vertical chain with double gripper |

| Tool changer number of pockets | 60 pockets |

| Maximum tool weight | 13.2 lbs. |

| Maximum tool length | 11.8" |

| Maximum tool diameter | 5.1"/3.1" |

| Machine weight | 10,185 lbs. |

| Machine maximum rated current | 31 A |