2019 MIKRON MILL P 500 U Dynamic 5-Axis VMC with 220 ATC and 14 x pallets

2019 MIKRON MILL P 500 U Dynamic 5-Axis VMC with 220 ATC and 14 x pallets

Description

The MIKRON MILL P 500 U Dynamic is a very robust, stable and accurate machining center in a gantry-type design. This 5-Axis milling solution is designed for high-performance machining applications. For 100 percent simultaneous operation, the machine has water-cooled direct drives in the rotary and swiveling axes, which can be clamped to reach even a higher stiffness during roughing.

Workpiece access is made easy by the big door and the short distance to the work table. Thanks to its unique concept and its modularity, the machine ensures precise-machining applications in both single part and fast, productive serial production.

-Gantry concept with shortest force flow which results in outstanding machining stability

-Solid, vibration-damping machine bed

-Thermo-symmetrical design and water-cooled components for long-term accuracy

-Extremely compact construction with big work area with user-friendly access

-Compact 220 position tool tower

-Machine and Spindle Protection (MSP) along all axis

-Integrated or third-party Automation in the smallest footprint

-HEIDENHAIN control enhanced by GF's smart machine

-Integral connectivity opening the path to Internet of Things integrations

-Ready for modular digital services

-Rotary/Tilt table with water-cooled direct drives. Clamping in 3-axis increases stability and maximizes tool life.

-The D (Dynamic) feature offers acceleration rates up to 1G.

-High performance 20,000 RPM Step-Tec HSK-A63 spindle delivers 120 Nm of torque for high metal removal, yet still providing the higher RPM's for fine surface quality.

-Smallest footprint in its class even with automation.

-High resolution glass scales on the X,Y and Z axes. Rotary encoders on the A and C axes.

-Fast HEIDENHAIN TNC640 control presents a neatly designed and user friendly interface.

-The MILL P 500 U D is subject to strict GF Machining Solutions quality requirements. Every machine is ISO 230-2(97) checked at the factory. The results are logged.

EQUIPPED WITH:

HEIDENHAIN TNC640 control

Electronic handwheel for control

Software "R-Connect" option

Machine Varient "D" (Dynamic)

RTT Rotary Tilt Table 200 kg Delphin

220 position tool tower

Lift up scraper chip conveyor

Mist extraction unit

Wash down system

Door media cabinet

"ITC" option (Intelligent Thermal Control)

"ITC-5X" option (5 Axis Intelligent Thermal Control)

"OSS" (Operator Support System)

"ISM" Intelligent Spindle Monitoring

PFP Power Fail Protection

Kinematics Opt

Calibration ball HEIDENHAIN KKH 250

Milling Option "ECONOWATT"

Rotating Window on front door

TSC Thru Spindle Coolant 18-80 bar (261 PSI-1,160 PSI)

Band filter system 950 l (251 gallon)

Touch probe infrared

Laser tool measuring system

Beacon option machine warning

Machine with EC conformity

Machine and spindle protection

Additional set of technical documentation

Direct measurement system 0.1 um (0.000004") glass scale positioning

Robot Interface

EROWA Robot Dynamic 150 Linear (ERD150L) includes:

-Transfer Unit (150 kg max)

-3m rail length

-Single machine interface kit

-Fixed arm to RCS Coupling for pallets (130 kg max)

-(1) chuck control and pneumatic tube set

-Storage for the following:

-7 levels (14 positions) for pallets (4 pos in LS)

-Single drawer loading station for pallets

-Load Station Rotating table with locking feature

-Safety fencing and line access door

-LED magazine lighting

-PC Panel for robot control

-Keyboard tray, keyboard and mouse

-Universal transformer

Cell Management Software JMS4.0 Production Line cell management software includes:

-1 x core system

-1 x JobManager Mikron

-1 x Machine Robot Connection

-1 x Setup and Load Station Manager

-1 x Machine Tool Management

-EWIS Manual Link

-EWIS Hand Reader USB

Machine is offered subject to availability, prior sale, and terms & conditions of FRANKE CNC Sales Agreement. To the best of our knowledge all details listed are deemed correct. It is the Buyer's responsibility to confirm all details including condition, capacity, suitability or performance and we encourage an under power inspection of the machine(s) and accessories prior to purchase.

Price quoted includes professional de-installation and shipping preparation by Seller.

Specifications

| Manufacturer | MIKRON MILL |

| Model | MILL P 500 U Dynamic |

| Year | 2019 |

| Condition | Used |

| Stock Number | 064514 |

| Working range Longitudinal X | 500 mm (19.7") |

| Working range Cross Y | 600 mm (23.6") |

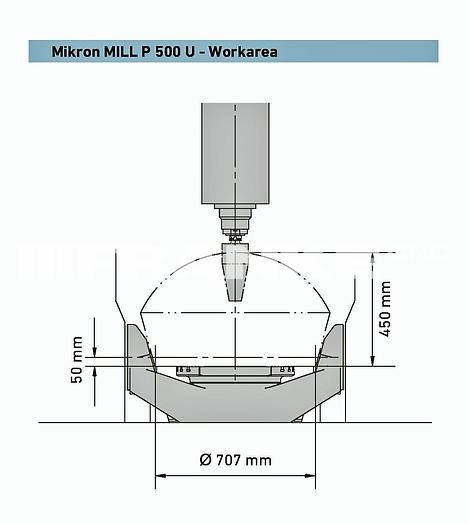

| Working range Vertical Z | 450 mm (17.7") |

| Maximum workpiece size | 707 mm (27.8") diameter x 450 mm (17.7") high x 200 kg (441 lb) |

| A-Axis | +91/-121 degrees |

| C-Axis | n x 360 degrees |

| Number of simultaneous axis | 5/5 simultaneous |

| Maximum acceleration X,Y,Z | 1 g |

| Feed rate rapid traverse X,Y,Z | 60 m/min (200 ft/min) dynamic version |

| Feed rate A axis (swivel) | 50 rpm |

| Feed rate C axis (rotary) | 60 rpm |

| Step-Tec Swiss made Spindle Power | 36 kW (48.2 hp) |

| Spindle RPM | 20,000 RPM |

| Spindle Torque | 120 Nm (88.5 ft. lbs) |

| Spindle Taper | HSK-A63 |

| Work table clamping surface | 398 mm x 398 mm (15.7" x 15.7") |

| Type of pallets | System 3R Delphin |

| Number of pallets | 14 (can be extended for more pallets) |

| Maximum workpiece weight | 200 kg (441 lbs) |

| Tool magazine number of positions | 220 position tool tower |

| Machine Weight | 13,000 kg (28,661 lbs) |